Views: 0 Author: Site Editor Publish Time: 2022-03-16 Origin: Site

The wood board laser die plate is mainly used in various precision die-cutting of boxes, dolls, plastics, electronics, etc., with an accuracy of ±0.2mm. Mainly used in printing and packaging, plastic packaging, leather, toys, advertising and other industries.

The main part of the group is the wooden board and the blade rule.

The material of the board is mainly poplar and birch, which are divided into: all poplar board, white birch panel, UV oil board, maple birch panel, and full birch board. The quality requirement is mainly that the deformation range is small, the thickness is uniform, the internal dense gap is small, the glue is not opened, and the surface is smooth and flat. The thickness is generally 15mm, 18mm, 20mm, 22mm, etc. The size is standard four by eight feet (1220*2440mm).

Commonly used blades have a thickness of 0.45 mm, 0.53 mm, 0.71 mm, and 1.05 mm. In addition, a common unit is pt, 1pt = 0.35146mm. The above thickness is converted to pt units and is 1.3pt, 1.5pt,

2pt, 3pt.

Accuracy range: ±0.2mm

Main materials: poplar, birch, eucalyptus and other plywood, die-cutting blades, steel holes, etc.

Mold features: the shape of the product required for stamping, the production process is simple, short delivery time, strong practicality and production capacity .

Equipment required: laser die cutter, automatic bending machine, manual die cutting equipment, etc.

Scope of application: mould, packaging, printing, electronic accessories, stickers, paper craft, EVA toys, etc.

The bottom plate is PVC which cut by laser cutting machine. Inserting the rules which bended by bender into the slit of PVC plate. The blade point height is 2.5-3mm, the accuracy is slightly worse, the range is ±0.2mm, the blade is easy to be deformed, can be recycled, and the price is cheaper than the etching die. It is mainly used in some double-sided adhesive materials, which are large in quantity and less complicated in process product.

Accuracy range: ±0.2mm

Main material: PVC board, die cutting blade, steel hole, etc.

Mold features: The best choice for self-adhesive stickers, electronic film, low cost, short delivery time

Equipment required: laser die cutter, automatic bending machine, manual die cutting equipment, etc.

Scope of application: printing, packaging, stickers, electronic flexible boards, electronic films, etc.

The bottom plate is made of high-toughness acrylic, which is laser-cut and insert the blade into slit. It is suitable for die cutting, handbags, leather goods, wallets, masks, garments and other industries.

Accuracy range: ±0.2mm

Main material: high toughness acrylic, die cutting blade

Mold features: transparent visual 360-degree punching effect, the shape and positioning hole positioning production is best, clearly see the edge of the product position, reducing production difficulty.

Equipment required: laser die cutter, automatic bending machine, manual die cutting equipment, etc.

Scope of application: leather goods, cloth, remote protective gear, soft PVC products, etc.

The steel first corrodes the approximate shape with the syrup, and then engraves the mold from the blade angle. Advantages: Cheap, processing blocks, no interface, and mold tolerances of ±0.1mm. Therefore, products with a general size requirement of ±0.1 mm or less can be corroded. Disadvantages: The hardness of the mold is a bit poor and cannot be repaired. The thickness of the corrosion mold is generally 1.2 mm, 1.5 mm, and 2.0 mm. Die life can generally be used to 100,000-200,000 strokes.

Accuracy range: ±0.1mm

Main material: high carbon steel A6061

Mold features: high precision of the blade point, the processing cycle time is much shorter than others, the production efficiency is high, and the blade flatness is high.

Equipment required: milling machine, engraving machine, grinding machine.

Scope of application: printing, electronic accessories, flexible circuit boards, stickers, high-precision products.

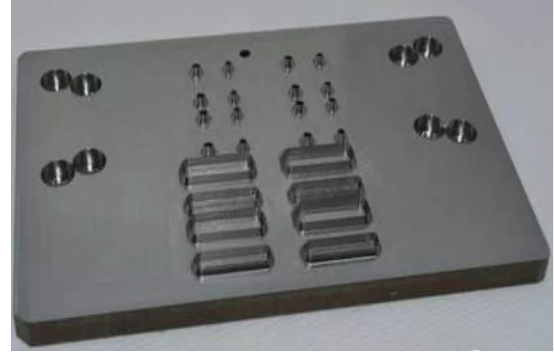

The mold and blade are integrated which engraved from a whole of steel board, and the hardness of the mold is increased by heat treatment. The mold tolerance is small ± 0.02mm, high hardness is suitable for aluminum foil, copper foil and other non-metal die-cut products. The mold can be reused. The blade can be used as a mold for sucking waste, and it can automatically discharge holes and other complex molds. The price is high and the processing cycle is slightly longer.

Accuracy range: ±0.02mm

Main material: DCMX, A6061

Mold features: It is the best choice for complex shape and high dimensional requirements. The blade has a sharp blade width of 0.003mm without interface, its flatness is 0.02mm, all dimensional tolerances are controlled at 0.02mm, and it has automatic discharge function. The edge can be repaired multiple times.

Required equipment: slow wire, fine carving machine

Scope of application: printing, packaging, electronic accessories, flexible circuit boards, high-precision products, etc.

Sign up for our newsletter

Ms. Judy Liu

Cell: +86 134 2095 0731

Email: sales@tsdlaser.com

Address

Building H, Sha Si Hi-Tech Park, Shajing, Baoan District, Shenzhen

Service

Copyright © 2021 Shenzhen TSD Laser Equipment Co., Ltd | Supported by leadong.com | sitemap 粤ICP备12005242号-9