Views: 324 Author: Site Editor Publish Time: 2021-11-24 Origin: Site

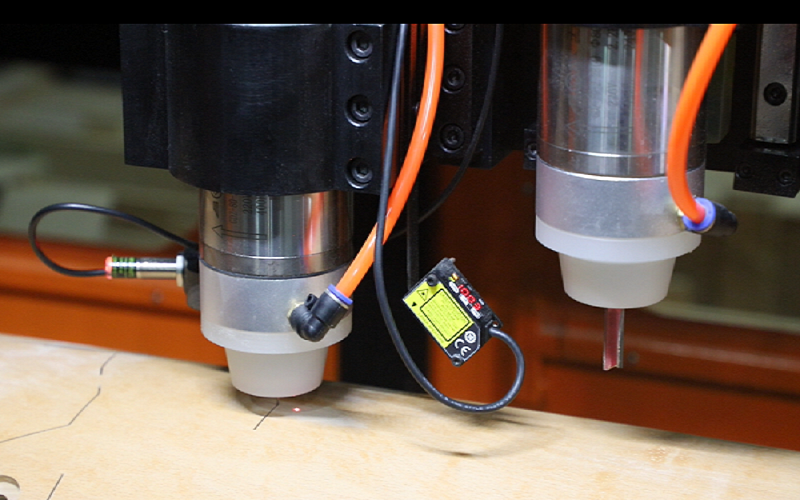

The CNC curved die board cutter is the key equipment for manufacturing peeling veneer. After combining with Internet technology, the CNC curved die board cutter has been developed, and the work efficiency and scope of use have been expanded.

What are the types of CNC curved die board cutter?

How to use CNC curved die board cutter?

What is the role of the pressure ruler in the work of a CNC curved die board cutter?

According to the driving mode of the main motion, the CNC curved die board cutter can be divided into the spindle drive type and the outer circle drive type. The spindle drive type can be divided into mechanical and hydraulic clamping according to the different clamping wood structures. The mechanical chuck rotary cutting machine is a single chuck rotary cutting machine with a simple structure and easy maintenance, but it has high labor intensity and low board yield, so it is more used in small and medium-sized enterprises. The hydraulically clamped chucks are divided into single chucks and double chucks. The hydraulic double-spindle rotary cutting machine has a high degree of automation, convenient operation, small wood core diameter, high board ejection rate, and good veneer quality. CNC curved die board cutter is mainly used in large and medium-sized enterprises. The wood section in the pinless rotary cutting machine is centered and driven by friction rollers. The wood core has the smallest diameter and the highest rate of board ejection. It is mainly used for the re-peeling of the wood core.

To cut flat and high-quality veneers with uniform thickness, the CNC curved die board cutter should ensure the most suitable cutting conditions, such as the main angle parameters, cutting speed, rotary knife position, and the position of the pressure ruler relative to the rotary knife. . These conditions are determined according to the wood species, the diameter of the wood section, the thickness of the veneer, the degree of wood hydrothermal treatment, and the structure and accuracy of the machine tool.

The main angle parameters of rotary cutting include rotary cutter grinding angle β, clearance angle α, cutting angle δ (∠δ=∠α+∠β), and feed angle k (∠k=90°+∠α). The position of the CNC curved die board cutter is determined by the height h of the cutter tip relative to the centerline of the chuck shaft and the feed angle k, which have a great influence on the quality of the veneer. The range of commonly used angle parameters: β=17°~23°, α=1°~+1°, k=89°~91°. The commonly used knife height h= -0.5~+0.5 mm, and the appropriate value can be selected after testing according to the thickness of the veneer and the degree of wear of the CNC curved die board cutter.

The function of the pressure ruler is to apply suitable pressure on the rotary cutting wood section to the blade of the rotary knife, which can prevent the wood splitting that is ahead of the blade due to the force of the rotary knife, improve the surface finish of the veneer, reduce the cracks on the back, and make the single The thickness of the board becomes more uniform, and at the same time, a part of the moisture is pressed out of the veneer to shorten the drying time of the veneer.

The installation and adjustment of the pressing ruler are carried out according to the horizontal distance H between the pressing ruler and the CNC curved die board cutter and the vertical distance V between the pressing ruler and the rotary blade. To avoid the bending of the wood section due to the force of the rotary knife, the pressure ruler, and the chuck shaft, the general CNC curved die board cutter should use the bending prevention press roll when the diameter of the wood section is below 250 mm. This can improve the veneer quality of the CNC curved die board cutter, reduce the diameter of the wood core, and increase the yield rate.

The advantages of a CNC curved die board cutter, such as power saving, simple operation, and convenient maintenance, make it popular among consumers. Shenzhen Test Laser Equipment Co., Ltd. has committed to providing the most suitable CNC curved die board cutter at a reasonable price, and whatever it takes to satisfy the customer’s needs.

Sign up for our newsletter

Ms. Judy Liu

Cell: +86 134 2095 0731

Email: sales@tsdlaser.com

Address

Building H, Sha Si Hi-Tech Park, Shajing, Baoan District, Shenzhen

Service

Copyright © 2021 Shenzhen TSD Laser Equipment Co., Ltd | Supported by leadong.com | sitemap 粤ICP备12005242号-9