Views: 0 Author: Site Editor Publish Time: 2022-03-25 Origin: Site

Before cutting the laser knife template, we often encounter multiple impositions. How to make them? First, draw a picture in CAD, arrange each graphic on a board, and then import it into the TSD cutting software. In this way, the laser die-cutting machine can process products in batches. Among them, although the typesetting process is very short, there is a lot of knowledge hidden in it. If the typesetting is slightly wrong, it will have a great impact on the cutting effect of the entire board. Even the entire knife template is scrapped and cut again, so what should be paid attention to in the typesetting process?

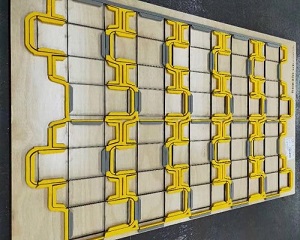

(Multiple box version)

1. Common edge cutting

Two or more knife templates are co-edged to form a combination, and a large batch of regular graphics should be co-ed as much as possible. Co-edge cutting can greatly shorten the cutting time and save raw materials.

2. Select the appropriate cutting path and divide the layers. Generally, the top of the knife template will be engraved with the name of the knife mold factory and the model of the knife plate. When engraving, it does not need to use too much power and does not need to cut through, so it needs to be sewed with the knife plate. into different layers.

3. Select the best cutting route to reduce cutting time and improve work efficiency.

(Multi-patterned version)

4. Lead setting

In the cutting process of the die cutter, in order to make the cutting seam well connected and prevent the burn at the beginning and the end, a transition line is often drawn at the beginning and end of the cutting, respectively called the lead and the tail. The lead and the tail are the workpieces themselves. It is useless, so it should be arranged outside the scope of the workpieces, and at the same time be careful not to set the lead wire in a sharp corner and other places that are not easy to dissipate heat. The connection between the lead and the kerf should use a circular arc transition as much as possible to make the machine move smoothly and avoid the burn caused by the corner stop.

(Multi-spell clothing tag board)

5. After cutting the knife board, if a whole board is used up and only the frame is left, it is necessary to remove the frame waste on the working table of the laser knife mold equipment as soon as possible, so that a new board can be placed to continue the cutting operation. Tested laser die-cutting machine has a device that automatically assists in loading and unloading sheets, which greatly reduces the operator's workload.

Sign up for our newsletter

Ms. Judy Liu

Cell: +86 134 2095 0731

Email: sales@tsdlaser.com

Address

Building H, Sha Si Hi-Tech Park, Shajing, Baoan District, Shenzhen

Service

Copyright © 2021 Shenzhen TSD Laser Equipment Co., Ltd | Supported by leadong.com | sitemap 粤ICP备12005242号-9