Views: 321 Author: Site Editor Publish Time: 2021-09-21 Origin: Site

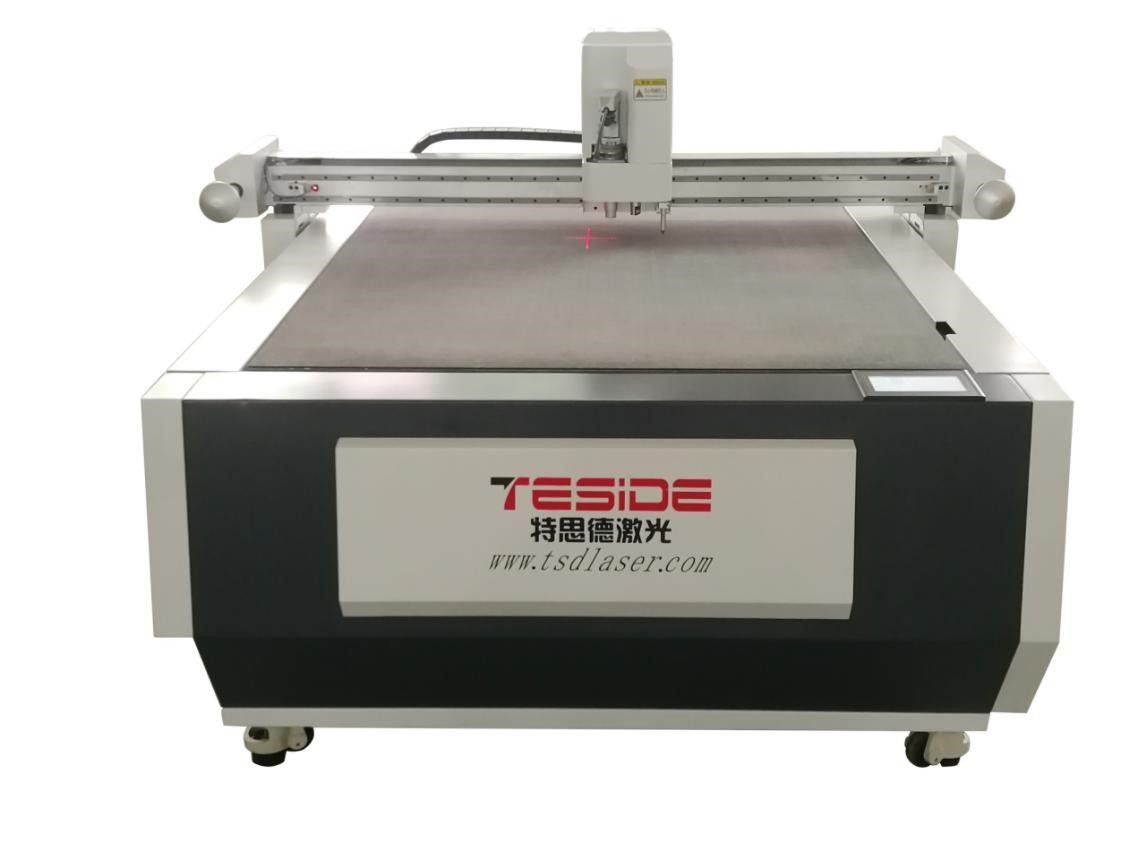

A flatbed die cutting machine is mainly used for die-cutting (full-broken, half-broken), creasing and bronzing operations, laminating, and automatic waste discharge. The flatbed die cutting machine uses steel knives, metal molds, steel wires (or stencils carved from steel plates) to apply a certain pressure through the embossing plate to roll and cut the printed products or cardboard into a certain shape. It is an important piece of equipment for post-press packaging processing and shaping.

What is the difference between a round die cutting machine and a flatbed die cutting machine?

What are the basic configurations of the flatbed die cutting machine?

What are the common functions of the flatbed die cutting machine?

The advantages and disadvantages of the flatbed die cutting machine are relatively speaking. Compared with the punching machine, it has the advantages of fast speed, convenient operation, and high efficiency. The disadvantage is that the price is more expensive relative to the punching machine, and compared to the round die cutting machine (round knife machine, also called the rotary die cutting machine), the flatbed die cutting machine has the advantage of low input and low price, and the precision is better than The round knife machine is high, but the disadvantage is that the speed is not as fast as the round knife machine.

The flatbed die cutting machine usually referred to here is the single-seat die-cutting machine that we often use without the nesting function, and it is also known as the high-speed precision die-cutting machine used in the one-shot type. Corresponding to the two-seat die-cutting machine, it can punch two times, punch the front and back the sleeve, and then the two-seat die-cutting machine is different from the two die-cutting machines used for small holes sleeves for punching.

The basic configuration of the single-seat flatbed die cutting machine includes

1. One unwinding machine, including one set of rewinding and unwinding shaft controlled by magnetic powder tension motor and one set of photoelectric induction

2. One die-cutting host, one set of main feed rack, one set of secondary feed rack, two sets of mechanical unwinding shafts, two sets of magnetic powder tension receiving shafts, one set of simple pressing roller base, and one set of the main machine mold base. One set of upper and lower templates, one set of large drawing head assembly, two sets of pressing rollers, two sets of glass scrapers.

3. There is one online host cutting table. The online cutting table can only perform online slicing operations, and cannot perform independent automatic slicing.

1. The flatbed die cutting machine can perform an independent punching operation.

2. The flatbed die cutting machine can perform compound die-cutting of two-layer materials.

3. The flatbed die cutting machine can carry out a separate stripping and waste discharge operation.

4. The flatbed die cutting machine can perform online slicing operations.

When the die-cutting manufacturer’s machine leaves the factory, the standard configuration is different due to different manufacturers. When we purchase the flatbed die cutting machine, we need to increase or decrease the configuration according to our configuration requirements, and the additional options of the configuration during this period are also It will affect the price of the flatbed die cutting machine. Therefore, in the process of adding flatbed die cutting machine configuration, it needs to be carried out in line with actual needs. "People-oriented, honesty first" has always been the development concept of TestSide. So they will try their best to satisfy your requirement of a flatbed die cutting machine.

Sign up for our newsletter

Ms. Judy Liu

Cell: +86 134 2095 0731

Email: sales@tsdlaser.com

Address

Building H, Sha Si Hi-Tech Park, Shajing, Baoan District, Shenzhen

Service

Copyright © 2021 Shenzhen TSD Laser Equipment Co., Ltd | Supported by leadong.com | sitemap 粤ICP备12005242号-9