Views: 0 Author: Site Editor Publish Time: 2022-03-20 Origin: Site

Comparison of advantages and disadvantages between manual knife die and laser knife die

The traditional manual knife mold machine is also called sawing machine or wood prototype, which is mainly used for manual knife mold sawing, drilling and related work. The principle is that the pedal controls the electric saw blade cutting board, absorbs air and removes dust, and the air cushion is suspended.

Traditional hand-made tool die processing technology

1. The manually drawn cutting line diagram of knife seam is not accurate, so it is impossible to make die-cutting plate with accuracy requirements.

2. The knife gap of manual sawing is poor, the seam width fluctuates greatly, and the offset, side slope and corner radian are large and not smooth.

3. Inlaying knife strips on the offset and inclined die-cutting base plate is labor-consuming and time-consuming, and the force is uneven during die-cutting operation, resulting in short service life of die-cutting.

4. When processing products with hand-made die-cutting board, the product scrap rate is high due to factors such as dimensional error and blade deflection.

5. Manual drilling and hand-held electric saw cutting form work have heavy work, large dust, polluting the environment and harmful to health.

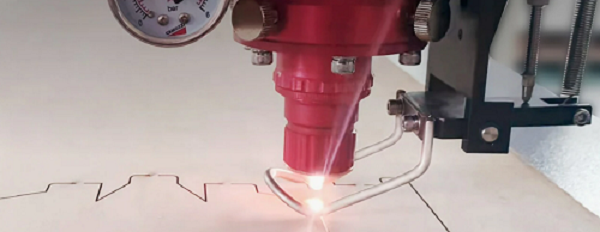

Laser knife mold machine is to use the strong energy of laser to deeply ablate the knife template, so as to achieve the goal of cutting knife. High speed, high precision, automatic numerical control, save labor, improve efficiency and quality of knife template.

Processing technology of laser cutter die machine

1. The operation is simple, the cutting slit design is completed on the computer, and various slit parameter settings are automatically generated based on software.

2. High quality, automatic laser cutting, no vibration deviation, high precision and stability.

3. High efficiency: large format, non-contact, 24-hour whole process operation, laser cutting die-cutting plate is more than twice as fast as that of sawing machine.

4. Competent for complex orders, not limited by the complexity of graphics. As long as it can be drawn, the machine can cut it, and the precision is very high, which can be controlled at about 0.05mm.

5. Short production cycle, high labor cost and low efficiency, and high profit of all day operation.

Therefore, the manual knife mold process is gradually eliminated and completely replaced by the laser knife mold.

Sign up for our newsletter

Ms. Judy Liu

Cell: +86 134 2095 0731

Email: sales@tsdlaser.com

Address

Building H, Sha Si Hi-Tech Park, Shajing, Baoan District, Shenzhen

Service

Copyright © 2021 Shenzhen TSD Laser Equipment Co., Ltd | Supported by leadong.com | sitemap 粤ICP备12005242号-9