Views: 318 Author: Site Editor Publish Time: 2021-11-18 Origin: Site

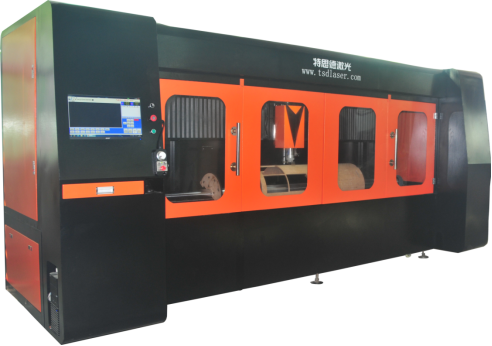

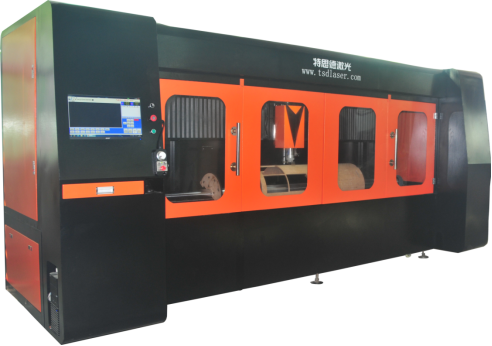

The CNC rotary cutting machine is used to process wood sections of a certain length and diameter into continuous veneer strips for the production of plywood, thin wood veneers, and other wood-based veneers. The main technical parameters of the CNC rotary cutting machine are the maximum length and diameter of the wood section that can be processed.

What are the characteristics of the CNC rotary cutting machine?

Compared with other similar equipment, what are the advantages of a CNC rotary cutting machine?

What are the relevant parameters when using the CNC rotary cutting machine?

1. The CNC rotary cutting machine uses a servo motor to drive the precision screw feed.

2. The CNC rotary cutting machine only needs to input the thickness of the plate to change the plate thickness, without changing the gear, and the rotary cutting precision is high.

3. For different wood species, the CNC rotary cutting machine can also be peeled together without affecting the thickness of the board.

4. The surface finish of the CNC rotary cutting machine is good, and it is not sensitive to the yin and yang surface of the wood.

5. The CNC rotary cutting machine saves electricity, is easy to operate, and is easy to maintain.

A CNC rotary cutting machine is one of the main pieces of equipment for veneer production, in a sense, it is more widely used than a planning machine. The CNC rotary cutting machine can be divided into two types: concentric peeling and eccentric peeling according to whether the wood segment rotates around its axis. The concentric rotary cutting machine is divided into two kinds: the card axis rotary cutting machine and the noncard axis rotary cutting machine. Eccentric rotary cutting can obtain beautiful radial patterns, but the productivity is lower than concentric rotary cutting.

CNC rotary cutting machine are generally large in size and complex in structure. The logs need to be centered before being used. If the centering is not correct, intermittent veneer strips or narrow veneers will be unscrewed when the peeler starts. The more broken veneers or narrow veneers, the more sapwood veneers of good quality are lost, which is not conducive to the continuity of production. Logs have curved, irregular cross-sections, and large and small heads (sharpness) at both ends, etc., which can easily cause the unscrewed veneers to be broken veneers. And that is a waste of wood. And when the log diameter is reduced to a certain extent, the peeling cannot be continued (that is, the remaining wood core causes wood waste).

1. The distance between the two clamping heads of the CNC rotary cutting machine determines the length of the peeling wood section, and therefore also the width of the unscrewed veneer strip. It has a maximum distance and a minimum distance. The length of the wood segment should not be greater than its maximum distance and not less than its minimum distance.

2. The height H from the centerline of the chuck axis of the CNC rotary cutting machine to the bed surface of the machine tool determines the maximum diameter D of the peeling wood section, D=2H-100mm. The maximum diameter of the peeled wood segment also depends on the maximum distance between the centerline of the chuck shaft and the tool bed.

3. The length of the rotary knife of the CNC rotary cutting machine is generally 50 mm longer than the maximum distance between the two chucks.

4. The rotation speed of the clamping shaft is related to the transmission mode of the transmission device of the CNC rotary cutting machine, and is determined according to the requirements to ensure the best rotary cutting conditions. The current numerical control CNC rotary cutting machine can be divided into two types according to the rotation speed of the clamping shaft during the rotary cutting process. One is that the rotation speed of the clamping shaft is fixed; the other is that the rotation speed of the clamping shaft increases with the rotation of the wood segment.

As a practical, convenient, green, and environmentally friendly production tool, the CNC rotary cutting machine has been widely used all over the world. Shenzhen Test Laser Equipment Co., Ltd. is a laser cutter mold equipment manufacturer established for more than ten years. We work with customers from design to completion to ensure that all technical requirements are met.

Sign up for our newsletter

Ms. Judy Liu

Cell: +86 134 2095 0731

Email: sales@tsdlaser.com

Address

Building H, Sha Si Hi-Tech Park, Shajing, Baoan District, Shenzhen

Service

Copyright © 2021 Shenzhen TSD Laser Equipment Co., Ltd | Supported by leadong.com | sitemap 粤ICP备12005242号-9