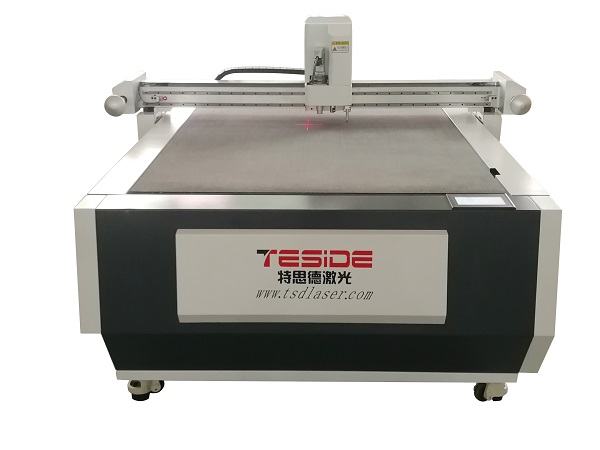

Digital Dotted Line Cutting Machine

Machine Technical Parameters:

Machine Model No. | TSD-EC1713 |

Processing Scale | 1700mm x 1300mm |

Cutting Table | All aluminum alloy honeycomb table |

Fixing Material Method | VACUUM adsorption |

Driving System | Servo Motor |

Transmission Mode | Linear guide rail + rack drive |

Configuration | Standard: Vibrating knife, pressing wheel, drawing pen, laser light positioning Optional: Drag knife, V cut, Foam Cut, CCD camera position system, CNC cutting mold |

MIN. Diameter of Circle | 3mm-6mm (according to materials) |

MAX. Speed | 2100mm/s |

MAX. Cutting Thickness | 60mm |

Transmission Port | Ethernet port |

Data Format Standard | HP-GL format, compatible with various AUTO CAD |

Control Panel | LCD screen, light-touched key-press |

Recommend Spare Parts | Vibration Knife |

Power Supply | 3 Phases 380V/50Hz |

Machine Size | 2600*2100*1450mm/ |

Machine Weight | 720KG |

HS Code | 8441100000 |

Main Features and Functions:

1. It is equipped with two interchangeable heads and an integral head frame, easy to change tools.

2. Seven-axis high-speed motion controller, modular installation, convenient for maintenance.

3. The cutting depth can be adjusted arbitrarily.

4. Simple parameter setting, different materials can be processed as long as the thickness and speed are set.

5. It can easily expand the functions of the upgraded equipment and load new modules.

6. Independent research and development operating system, simple operation, powerful function, lifetime upgrade for machine software.

7. High-speed vibrating head, the high-quality cutting effect can be achieved at high-efficiency cutting speed.

8. Integral partition suction, only in the cutting area that is working, the suction function is automatically turned on,

and the suction in the non-working area is disabled.

9. Positioning function: use laser light to accurately position.

10. Drawing function: It can draw various high-precision patterns.

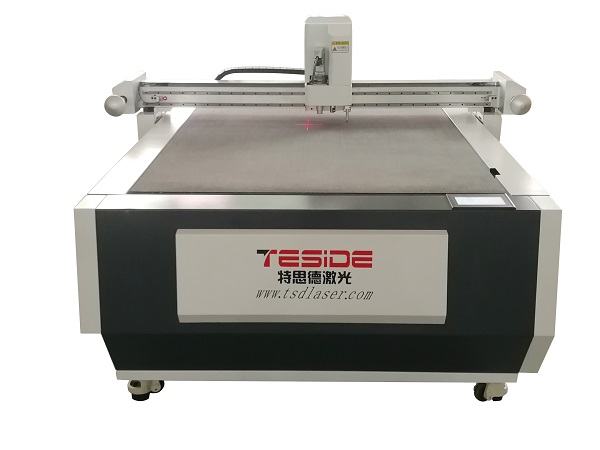

Digital Dotted Line Cutting Machine

Machine Technical Parameters:

Machine Model No. | TSD-EC1713 |

Processing Scale | 1700mm x 1300mm |

Cutting Table | All aluminum alloy honeycomb table |

Fixing Material Method | VACUUM adsorption |

Driving System | Servo Motor |

Transmission Mode | Linear guide rail + rack drive |

Configuration | Standard: Vibrating knife, pressing wheel, drawing pen, laser light positioning Optional: Drag knife, V cut, Foam Cut, CCD camera position system, CNC cutting mold |

MIN. Diameter of Circle | 3mm-6mm (according to materials) |

MAX. Speed | 2100mm/s |

MAX. Cutting Thickness | 60mm |

Transmission Port | Ethernet port |

Data Format Standard | HP-GL format, compatible with various AUTO CAD |

Control Panel | LCD screen, light-touched key-press |

Recommend Spare Parts | Vibration Knife |

Power Supply | 3 Phases 380V/50Hz |

Machine Size | 2600*2100*1450mm/ |

Machine Weight | 720KG |

HS Code | 8441100000 |

Main Features and Functions:

1. It is equipped with two interchangeable heads and an integral head frame, easy to change tools.

2. Seven-axis high-speed motion controller, modular installation, convenient for maintenance.

3. The cutting depth can be adjusted arbitrarily.

4. Simple parameter setting, different materials can be processed as long as the thickness and speed are set.

5. It can easily expand the functions of the upgraded equipment and load new modules.

6. Independent research and development operating system, simple operation, powerful function, lifetime upgrade for machine software.

7. High-speed vibrating head, the high-quality cutting effect can be achieved at high-efficiency cutting speed.

8. Integral partition suction, only in the cutting area that is working, the suction function is automatically turned on,

and the suction in the non-working area is disabled.

9. Positioning function: use laser light to accurately position.

10. Drawing function: It can draw various high-precision patterns.

Sign up for our newsletter

Ms. Judy Liu

Cell: +86 134 2095 0731

Email: sales@tsdlaser.com

Address

Building H, Sha Si Hi-Tech Park, Shajing, Baoan District, Shenzhen

Service

Copyright © 2021 Shenzhen TSD Laser Equipment Co., Ltd | Supported by leadong.com | sitemap 粤ICP备12005242号-9