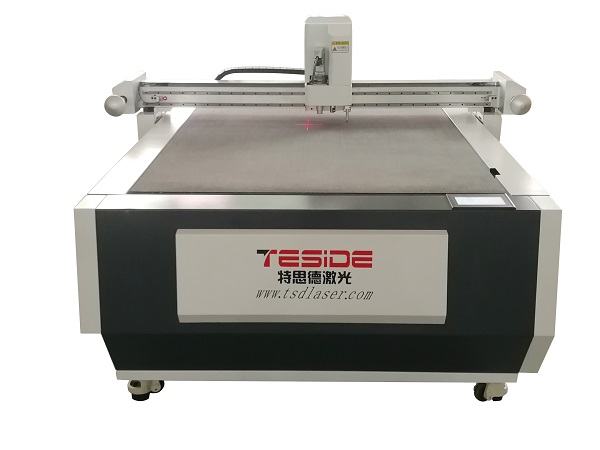

CNC Cutter Paperboard Box Digital Cutting Machine

Machine Technical Parameters:

Machine Model No. | TSD-HC2516/TSD-HC1713/TSD-HC1310 |

Processing Scale | 2500mm x 1600mm/1700x1300mm/1300 x 1000mm |

Cutting Table | All aluminum alloy honeycomb table |

Fixing Material Method | VACUUM adsorption |

Driving System | Servo Motor |

Transmission Mode | Linear guide rail + rack drive |

Configuration | Standard: Vibrating knife, pressing wheel, drawing pen, laser light positioning Optional: Drag knife, V cut, Foam Cut, CCD camera position system, CNC cutting mold |

MIN. Diameter of Circle | 3mm-6mm (according to materials) |

MAX. Speed | 2100mm/s |

MAX. Cutting Thickness | 60mm |

Transmission Port | Ethernet port |

Data Format Standard | HP-GL format, compatible with various AUTO CAD |

Control Panel | LCD screen, light-touched key-press |

Recommend Spare Parts | Vibration Knife |

Power Supply | 3 Phases 380V/50Hz |

Machine Size | 2600*2100*1450mm/ |

Machine Weight | 720KG |

HS Code | 8441100000 |

Main Features and Functions:

1. High-strength frame-type fuselage is stable and not deformed.

2. It can cut materials with a height of 60mm, and can cut all kinds of cardboard, corrugated paper, and honeycomb paper.

And packaging lining materials such as pearl cotton EVA.

3. Aviation honeycomb aluminum alloy adsorption platform, with table compensation, good sample running effect.

4. Double-tool holders design, good effect, and strong expansion ability (most of the peers are single-tool holders)

5. Full rack drive system to ensure high precision and high speed.

6. Independent research and development operating system, simple operation, powerful function, lifetime upgrade for machine software.

7. It can be equipped with a high-speed digital proofing machine, with good printing effect and fast speed.

It can follow the mass effect of the printing machine and build a one-stop solution for small batches of packaging and printing, replenishment, and proofing.

8. 12 years of equipment manufacturing experience in the packaging industry, rich service team experience, and timely response for customers.

FAQ

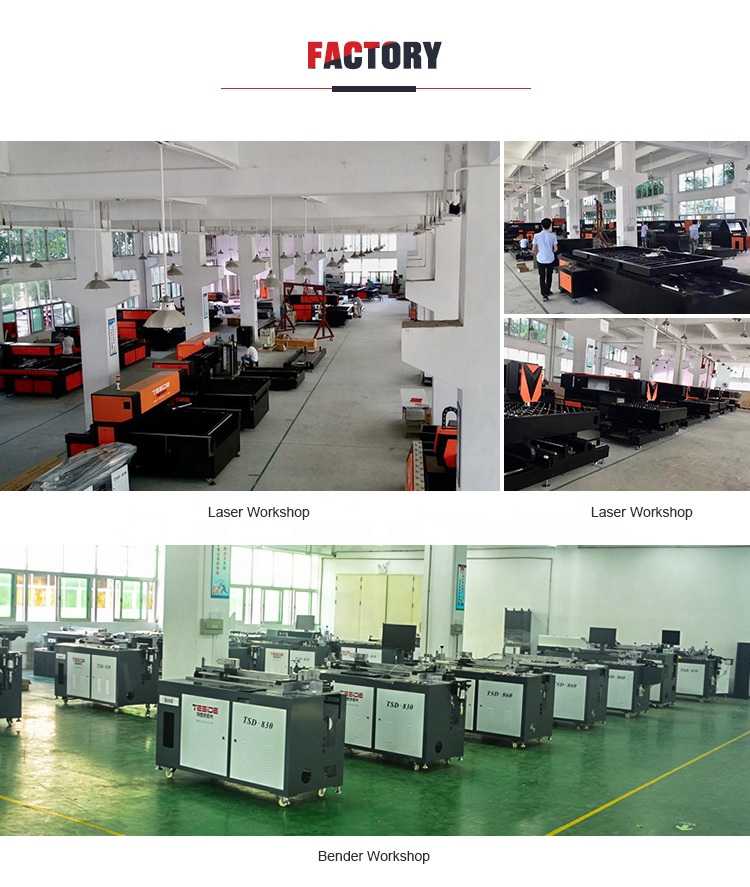

We have served more than 5000 users and our die-making equipment installed in over 70 countries including European & American countries.

Die laser cutting machine for 6-30mm plywood cutting, which is a matched die-making machine for die board making used in packing, printing, and advertising industries.

One set die laser cutting machine, one set auto bending machine and some assistant manual tools will be recommended.

The regular auto bender supports 1.42x 60mm max cutting rule processing, and the customized one supports 1 x 150mm cutting rule processing.

Yes, sure thing. Just feel free to send us the die-cutting drawing in DXF format, and process videos of running samples by our machine will be sent to you. Also, the samples could be sent to you by DHL based on your account if needed.

A full set die-making machine with related device systems will be offered by TSD. Just need customers to prepare a set 7.5kw/10P air compressor and the right electricity and space. Electricity in China is 220 50Hz single phase & 380V 60Hz 3 phase. A set voltage transformer which with stabilization functions will be prepared by customers is necessary. The working space needed for a set 400watt laser and a set auto bender is around 23-25 square meters.

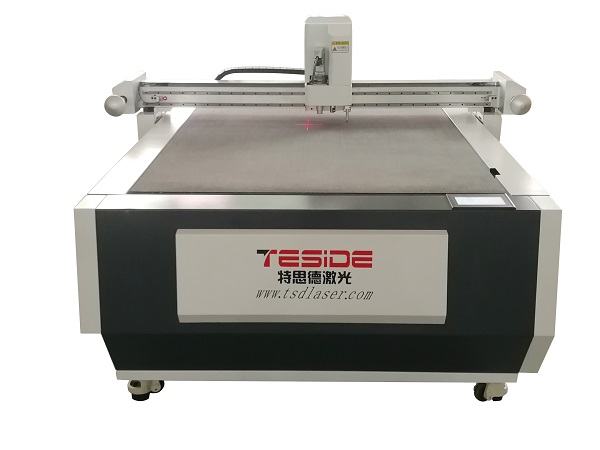

CNC Cutter Paperboard Box Digital Cutting Machine

Machine Technical Parameters:

Machine Model No. | TSD-HC2516/TSD-HC1713/TSD-HC1310 |

Processing Scale | 2500mm x 1600mm/1700x1300mm/1300 x 1000mm |

Cutting Table | All aluminum alloy honeycomb table |

Fixing Material Method | VACUUM adsorption |

Driving System | Servo Motor |

Transmission Mode | Linear guide rail + rack drive |

Configuration | Standard: Vibrating knife, pressing wheel, drawing pen, laser light positioning Optional: Drag knife, V cut, Foam Cut, CCD camera position system, CNC cutting mold |

MIN. Diameter of Circle | 3mm-6mm (according to materials) |

MAX. Speed | 2100mm/s |

MAX. Cutting Thickness | 60mm |

Transmission Port | Ethernet port |

Data Format Standard | HP-GL format, compatible with various AUTO CAD |

Control Panel | LCD screen, light-touched key-press |

Recommend Spare Parts | Vibration Knife |

Power Supply | 3 Phases 380V/50Hz |

Machine Size | 2600*2100*1450mm/ |

Machine Weight | 720KG |

HS Code | 8441100000 |

Main Features and Functions:

1. High-strength frame-type fuselage is stable and not deformed.

2. It can cut materials with a height of 60mm, and can cut all kinds of cardboard, corrugated paper, and honeycomb paper.

And packaging lining materials such as pearl cotton EVA.

3. Aviation honeycomb aluminum alloy adsorption platform, with table compensation, good sample running effect.

4. Double-tool holders design, good effect, and strong expansion ability (most of the peers are single-tool holders)

5. Full rack drive system to ensure high precision and high speed.

6. Independent research and development operating system, simple operation, powerful function, lifetime upgrade for machine software.

7. It can be equipped with a high-speed digital proofing machine, with good printing effect and fast speed.

It can follow the mass effect of the printing machine and build a one-stop solution for small batches of packaging and printing, replenishment, and proofing.

8. 12 years of equipment manufacturing experience in the packaging industry, rich service team experience, and timely response for customers.

FAQ

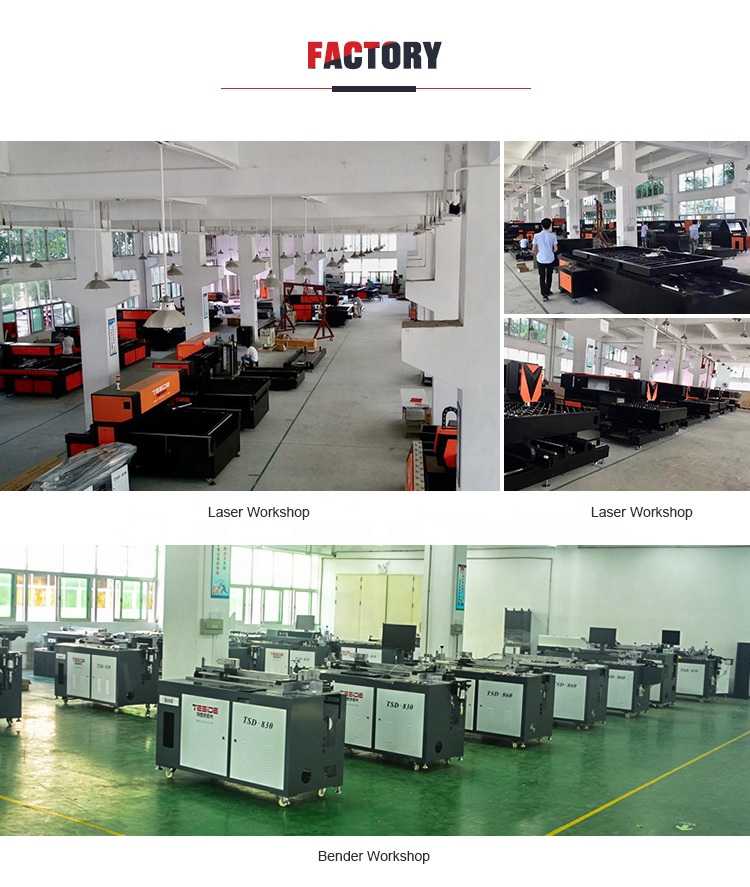

We have served more than 5000 users and our die-making equipment installed in over 70 countries including European & American countries.

Die laser cutting machine for 6-30mm plywood cutting, which is a matched die-making machine for die board making used in packing, printing, and advertising industries.

One set die laser cutting machine, one set auto bending machine and some assistant manual tools will be recommended.

The regular auto bender supports 1.42x 60mm max cutting rule processing, and the customized one supports 1 x 150mm cutting rule processing.

Yes, sure thing. Just feel free to send us the die-cutting drawing in DXF format, and process videos of running samples by our machine will be sent to you. Also, the samples could be sent to you by DHL based on your account if needed.

A full set die-making machine with related device systems will be offered by TSD. Just need customers to prepare a set 7.5kw/10P air compressor and the right electricity and space. Electricity in China is 220 50Hz single phase & 380V 60Hz 3 phase. A set voltage transformer which with stabilization functions will be prepared by customers is necessary. The working space needed for a set 400watt laser and a set auto bender is around 23-25 square meters.

Sign up for our newsletter

Ms. Judy Liu

Cell: +86 134 2095 0731

Email: sales@tsdlaser.com

Address

Building H, Sha Si Hi-Tech Park, Shajing, Baoan District, Shenzhen

Service

Copyright © 2021 Shenzhen TSD Laser Equipment Co., Ltd | Supported by leadong.com | sitemap 粤ICP备12005242号-9